Brother

HL3170CDW "Print Unable 0A" Problem [Solved]

I bought a 2nd hand Brother HL3170CDW color printer the

other day on a local used goods website:

The printer was listed for a good price, and came with three

toner cartridges, so I jumped on the deal. But, while the machine arrived in great

cosmetic condition, it did have one major problem...it arrived DOA.

The First Sign of Trouble

Whenever I buy a used piece of equipment, I clean its

exterior and blow it out with my compressor before bringing it into the

house. While doing this, I noticed the Brother

HL3170CDW color printer cooling fan didn't make the characteristic whirring

sound that fans typically produce when compressed air is pushed through

them. They usually freewheel and make a loud

high-pitched whine with a rapidly increasing pitch. But in the case of the Brother HL3170CDW color

printer, the only sound I heard was a kind of dull click, despite several

attempts.

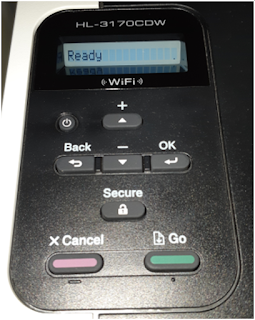

This Printer Was Definitely Troubled

After cleaning up the Brother HL3170CDW color printer and

bringing it inside, I plugged it in. The

machine powered up, but the only thing I got from it was the following error message

on the control panel:

Looking online, I discovered this error indicates a mechanical

failure of some kind.

No further

details were given. You are supposed to bring the machine into the dealer.

Into Troubleshooting Mode We Go

Springing into troubleshooting mode, I tried a bunch of the

typical things that help to isolate problems with printers.

1.

I re-seated all of the cartridges

2.

I re-seated the print tray

3.

I opened up all of the flip-out trays (manual

paper feeder, paper jam)

None of these measures worked.

How Laser Printers Start Up

Laser printers are actually examples of what would today be

called an Internet of Things (IoT) device, embedded system, single

board computer or even single-purpose computing device. All of these different names really just mean

that this machine is designed to satisfy a narrow list of requirements for

which it has been pre-configured.

Part of the pre-configuration for most special-purpose

devices is to perform something called a Power

On Self Test (POST). This is a small

routine that checks to make sure that the basic building blocks of the device

(CPU, RAM, NET, DEVICES) are available and sufficiently provisioned for the

device to achieve a known initial state. This is because devices like a Brother

HL3170CDW color printer act as a finite

state machine, and need a known initial state.

Knowing this, I started to think about the way that I would

design the POST for a modern device like the Brother HL3170CDW color

printer. If it were up to me, I would

check to make sure the following was available and working:

A.

The Central Processing Unit (CPU)

B.

The memory (RAM)

C.

The means of receiving print jobs (I/O)

D.

The means of moving paper though the machine

(DEVICE)

E.

The presence and proper availability of toner

(CONSUMABLE)

F.

The presence and proper availability of a fuser

to bond toner to paper (DEVICE)

But, due to my inkling of first signs of trouble, I felt I

needed to add one more device to this list.

The fan.

Fans and Computers

Fans have been a fact of life in computing for a long

time. They are a cheap and easy way to

keep computers cool. They have been

present in the power supplies of powerful Intel-based Personal Computers like

the IBM PC since the 80's and have been directly mounted to the top of the CPU

in most Personal Computers since the 90's.

People Hate Loud Fans

Originally, a "case fan" or "muffin fan"

was black, about 4 inches wide and it had two wires (red/black) leading out of it. Case fans also used to be simple - they ran at a constant

speed of around 2000 RPM. This could be kind of loud for some people, so in the old days we used to solder a 2W @ 100 Ohm resistor in series with one of the wires to quieten down the fan, by bringing down its RPMs to around 1000 RPM. Besides making it a lot more quiet, this also extended the life of the fan.

Fans are Smart Now

In response to these measures, "smart" fans started

to emerge about 20 years ago. You know your fan is "smart" if it has more than two wires coming out of it. Smart

fans can range from silent mode (0

RPM) to performance mode (~2200 RPM) completely through software and integration with a microcontroller. They control their speed by "slicing" the power coming into them at differing angles, a

technique known as Pulse Width

Modulation.

How to Troubleshoot a Fan

Suspecting that there might be something wrong with the fan

in the Brother HL3170CDW color printer, I shone a light into the fan outlet

area and plugged the printer in. What I

saw was the fan moving a little tiny bit, then stopping, then moving a little

bit, then stopping. It looked a lot like something was blocking the fan

So I unplugged the printer once again and got a thin piece of non-conducting

wood. I then used the piece of wood to manually move the fan blades to see if they would rotate through a full 360 degrees. They wouldn't, which confirmed my suspicions that they were being obstructed by something.

Disassembling a Brother HL3170CDW Color Printer

Thinking I was onto something, I undertook the challenge of disassembling the Brother HL3170CDW color printer. Taking one apart turned out to

be fairly easy. First, I unplugged

the unit. Next, I started removing obviously

related screws.

I quickly found out that there are just two screws involved; one is revealed by lifting the top deck of the printer. It is located at the front right corner. The other is behind the rear flip down cover, it is located at the rear top left corner as you look at the back of the printer.

The screws were the same size

and both had a Phillips head, so no special tools were required to remove

them.

Be very gentle here. Taking the plastic side panel off was a bit challenging

until I realized that I needed to gently depress some retaining clips

that are only accessible through little slots in the top right side of the

printer. I did this with a steak knife. I then had to navigate the two plastic

outrigger tabs off of little centering posts that also acted as screw mounts. Once the clips were disengaged, the cover easily

cantilevered off from the top to the bottom, more or less.

The D08K-24TS6 04B 8025 24V 0.14A axial cooling fan

With the right side panel removed, the cooling fan for the Brother

HL3170CDW color printer was revealed, so I examined it closely. It is a D08K-24TS6

04B 8025 24V 0.14A axial cooling fan with 3 wires coming out of it, which makes it a smart fan. Using my the non-conductive

piece of wood once again, I tried once again to rotate the fan blades through a

full 360 degrees, but they would still not turn smoothly. I then removed the fan unit entirely from the

printer by unplugging it and moving its three wires out of their retaining clip.

Powering Up a Fanless Brother HL3170CDW Color Printer

Powering up a fanless Brother HL3170CDW color printer was

unfruitful. It immediately gave a Print Unable 0A error.

Disassembling the D08K-24TS6

Having nothing to lose at this point, I decided to take

apart the D08K-24TS6 axial cooling fan to see what I could see, and maybe service it. Now, these four-inch fan units are not really designed

to be serviced, mostly because they are so cheap. But in the old days I used to have to take my

computer fans apart because replacement fans were so hard to find in my home

country in those pre-Internet times.

Besides,

99% of the time it is the bearings that go wrong in any fan, and you can get a lot

more life out of one by just cleaning the blades of dust buildup and putting a drop

of 3-in-1 oil in the bearings. This also goes for house fans, not just computer fans.

To take apart a typical "muffin" style fan you

usually have to follow these steps:

I.

Remove the fan from the computer

II.

Remove the label on the top of the fan

III.

Remove any retaining clips that are present

IV.

Orient the fan so the frame is pointing toward

you

V.

Using two thumbs, apply equal pressure to as

many blades of the fan as possible

VI.

The fan blade assembly should just pop off

fairly easily

VII.

If it doesn't, you are missing a retainer

somewhere

Fan Hacking

In the case of the D08K-24TS6, there was a significant (but

not infinite) amount of resistance at first, and then the fan assembly came

apart. As it turns out, the D08K-24TS6

features a "circlip free" retaining strategy that utilizes four posts with locking lobes to hold the fan together. The fan blade

assembly is rotated onto the four posts using special guide channels molded into the inside

of the fan blade assembly.

In the case

of this Brother HL3170CDW color printer, either the fan had never been assembled

correctly, or it had been somehow dislodged from its properly assembled state.

Whatever the case, the four posts were now blocking

D08K-24TS6 fan blade assembly, and preventing it from turning properly.

So I cut the four

posts off with a pair of small, sharp diagonal wire cutters.

The reason why I knew I could do this was simple. Fans are simple little motors that use basic

principles of magnetism to operate. They

feature a little permanent magnet that chases a rotating magnetic field that is

created by a set of carefully wound coils of copper wire. Even without the retaining posts, the

internal magnetic fields would be more than strong enough to keep the fan blade

assembly in place, especially considering the fact that this particular fan

resided in a molded enclosure. There was

literally nowhere for the fan blade assembly to go.

With the posts cut off, the fan blade assembly slid easily back

into place, and the fan was then able to rotate freely. Powering up the machine immediately resulted

in the sweet sound of the fan spinning up to maximum RPM, as well as the other sounds that laser printers tend to emit when they start up:

- Paper advance mechanism cycling

- Fuser relay clicking

- ...and so on

Sweet Success

Once the Brother HL3170CDW color printer had completed

its POST, I was presented with this screen:

Sources:

https://en.wikipedia.org/wiki/Computer_fan

https://en.wikipedia.org/wiki/Computer_cooling

https://en.wikipedia.org/wiki/Pulse-width_modulation

https://www.cnet.com/reviews/brother-hl-3170cdw-review